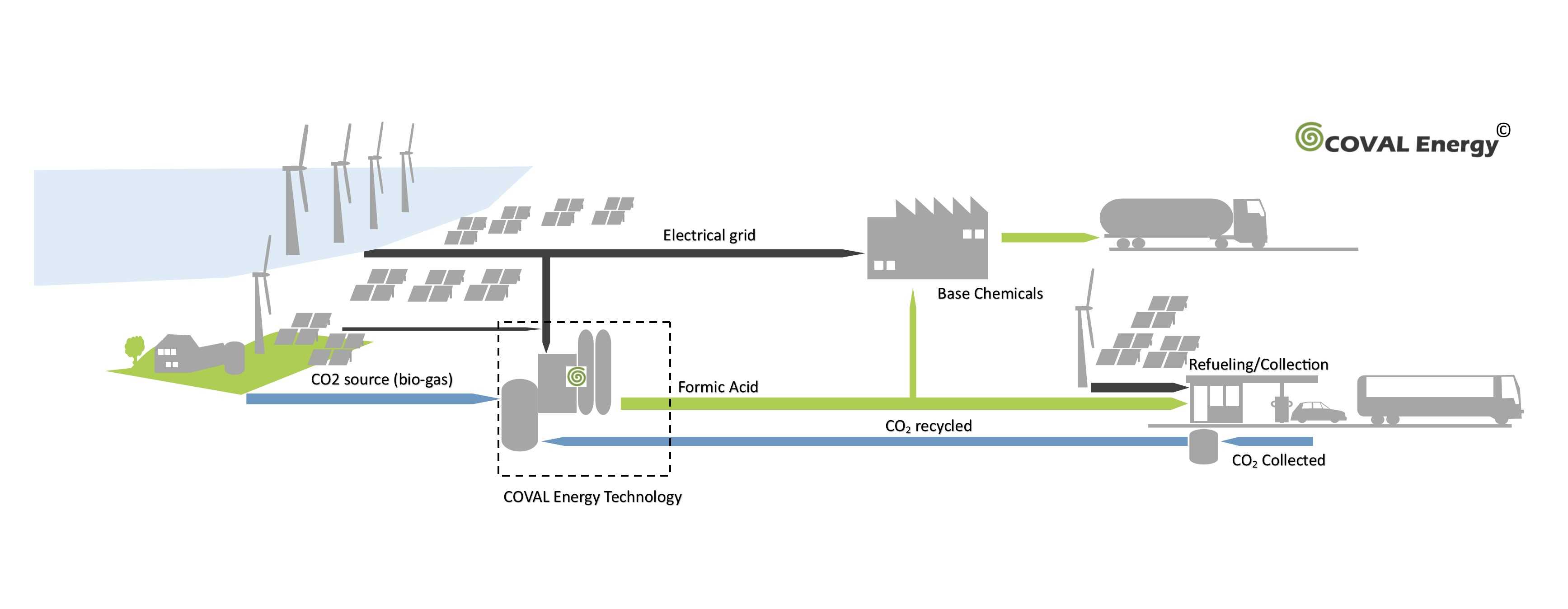

The main challenge is to develop innovative processes that are based on the principle of zero-waste or that are carbon-neutral.

Our approach is centered on the reactor design for electrochemical cells, resulting in an efficient and practical electro-catalytic process for converting CO2 into bulk chemicals. Operating conditions, material and energy balances, and the reactor configuration are optimized in terms of:

- The feeding of CO2 to the electrochemical reactor and the electric energy requirements.

- Choice of the materials used for the electrodes and the ion-exchange membrane to assure a low over-potential and a high flux of hydrogen ions across the membrane.

- Location and configuration of the electrodes in the reactor, combining several features of electrodes and the ion exchange membrane to assure a high electric current density.

- The overall process is based on a modular design, the use of an electrochemical cell permits scale-up to a significant plant based on an array of electrochemical cells.

- High selectivity and high conversion for a number of products: formic acid (CH2O2), carbon monoxide (CO), or methanol (CH3OH), minimizing the downstream processing to obtain the desired specifications.